Factory Provide Antifoam Paper Making Pulp Oil Use Defoamer

Factory Provide Antifoam Paper Making Pulp Oil Use Defoamer SY-8302 defoamer Product Description SY-8302 defoamer is a n

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | Sy-4326 |

| Appearance | Liquid |

| Kind | Waste Paper Deinking Agent |

| Producing Flow | Pulping Chemical |

| Supplier | Suny |

| Certificate | SGS |

| Application | Paper Making |

| Customization | Acceptable |

| Sample | Available |

| Customized | Available |

| Applications | Water Treatment |

| Product Name | Sy-4326 Defoamer |

| Transport Package | 200kg or 1000kg Buckets |

| Specification | Polyether |

| Trademark | Suny |

| Origin | China |

| HS Code | 3402900090 |

| Production Capacity | 100 Tons/Year |

Product Description

Factory Provide Antifoam Paper Making Pulp Oil Use Defoamer

SY-8302 defoamer

Product Description

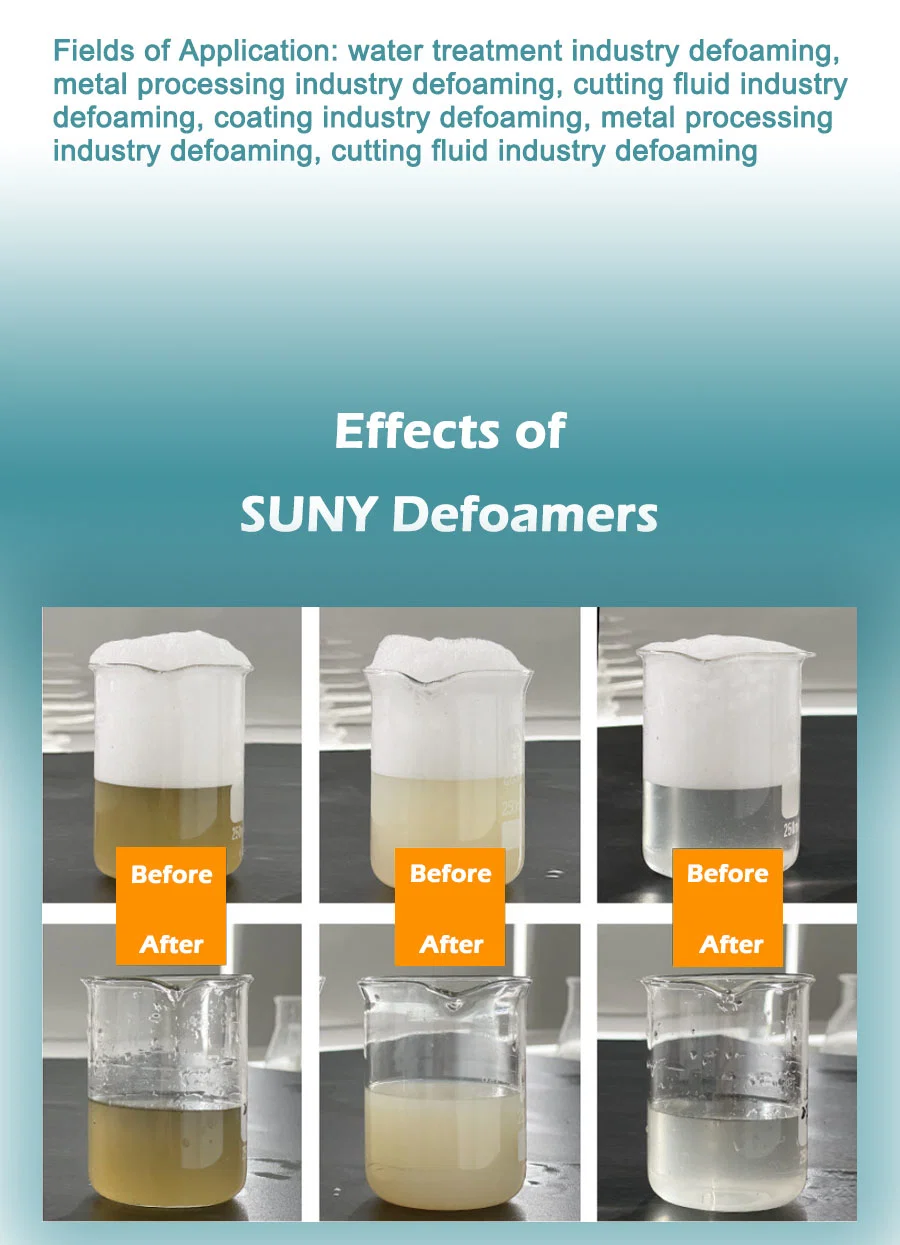

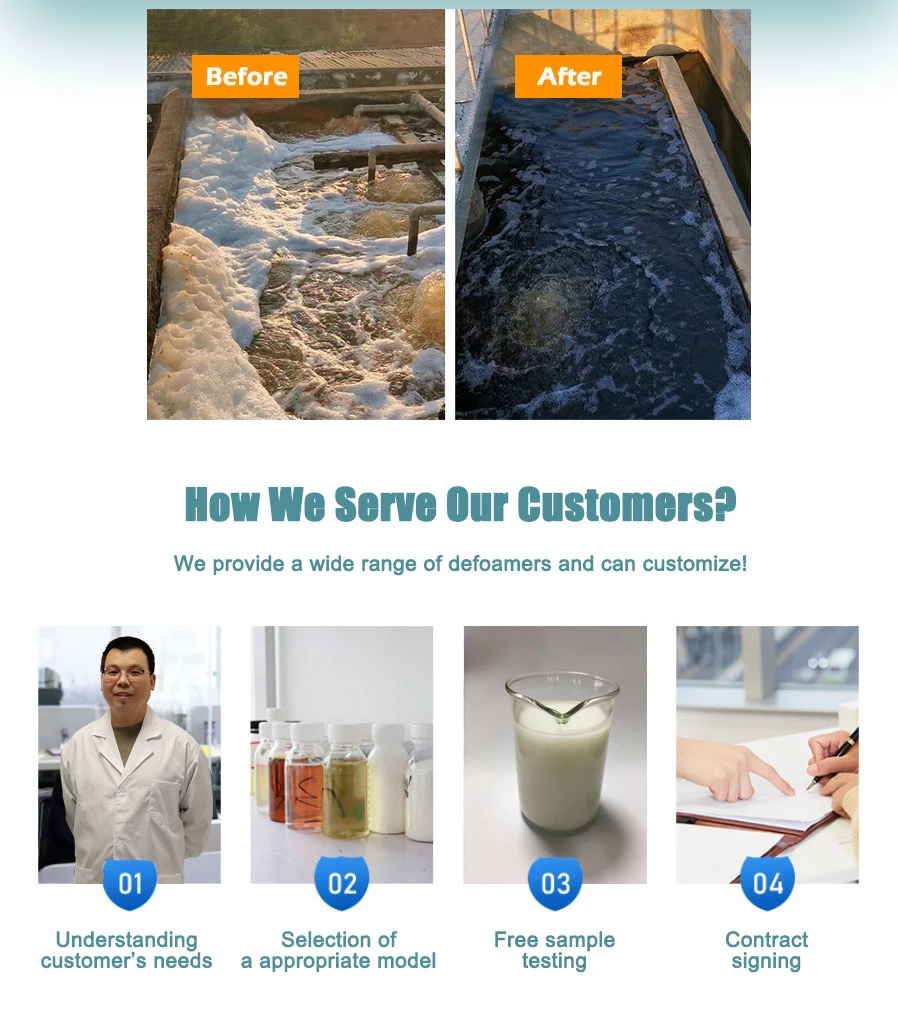

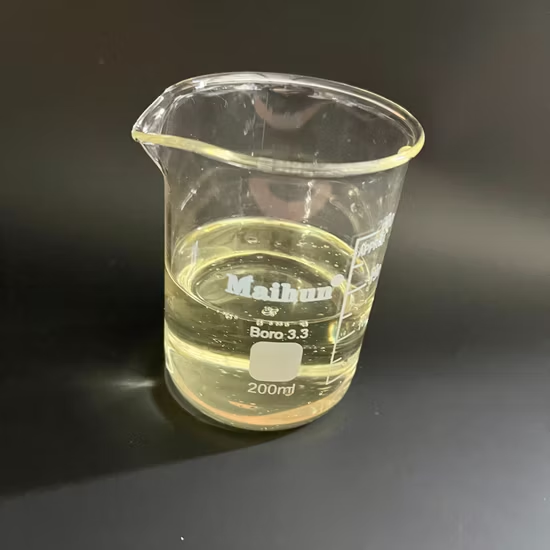

SY-8302 defoamer is a new organ silicon emulsion type defoamer, developed to resolve the foam problems for pulping procedure, bleaching industry, water treatment industry.The major ingredients are modified polysiloxane, special dispersant and other assistants.

This defoamer, suitable to be used under the conditions of high temperature, has strong ability to quickly eliminate the foams resulted from lignin and other surface active agents. It has many advantages, such as: very stable emulsion, low consumption, not easy to adhere to the machines and mesh, enhancing the work efficiency of the machines, sizing percentage, and pulp washes level. It is very useful to save the production and raw materials cost for the mills.

Product Features

* Quickly eliminate and suppress foams for long time;

* Effectively reduce residual alkali;

* Reduce pulp draining due to foams;

Characteristics:

| Appearance | White emulsion |

| Density | 1.000±0.100 |

| viscosity(mPa·s,25ºC) | 500~1000 |

| pH value (25ºC) | 6.0~8.0 |

| stability | Underlayer sediment volume ≤1cm3 |

| Emulsion type | Nonionic |

How to use:

This defoamer should be added to black liquor storage and centrifugal serene directly or after proper dilution. Generally it is necessary to use 300g~800g defoamer for one ton of dry paper. For the other fields, the actual amount should be determined according to the tests result.

Precautions:

In case freeze took place during transportation and storage, the defoamer should be unfreezed naturally, and stired evenly before use.

6. Package and Storage

Use 200kgs, 1000kgs packages, or negotiated packages. Sealed and stock under room temperature, away from light. Avoid the defoamer exposed to extremely cold or hot enviroment. Shelf life is 1 year.

Security

Avoid contact with eyes and respiratory system. Once happen, please wash with lots of clear water, to see a doctor is necessary if the situation is serious.